SANTA CRUZ (MAXREFDES23#):IO-LINK光传感器

概述

Santa Cruz是世界上最小的IO-Link光传感器,集成6个传感器:环境光(亮光)、红光、绿光、蓝光、红外以及温度传感器,全部集成在6.5mm x 25mm微小印刷电路板(PCB)上。Maxim Integrated、Renesas® Electronics和Technologie Management Gruppe Technologie und Engineering (TMG TE)通力协作,将Santa Cruz设计为兼容第1.1/1.0版IO-Link协议的光传感器参考设计。Santa Cruz设计包括行业标准的Maxim Integrated IO-Link设备收发器(MAX14821);Renesas超低功耗、16位微控制器(RL78),使用TMG TE的IO-Link设备栈和Maxim Integrated光传感器(MAX44008)。请参照图1。从上世纪80年代以来,工业现场总线已经支持智能设备、较快地安装、减少接线,并且更容易维护。然而,唯一、普遍可接收的现场总线的缺失,也引起了混淆、培训挑战、高成本以及设备之间兼容的问题1。IO-Link是第一种开放式、现场总线不可知、低成本、点对点串行通信总线协议,用于与传感器及执行器通信,已经被采纳为国际标准(IEC 61131-9)2。IO-Link最终标准化了全世界工业设备的互操作性。IO-Link可直接由PLC操作,或者集成到任何标准现场总线,使其快速成为与Santa Cruz (MAXREFDES23#)等智能设备通信的事实标准。既简单又智能的IO-Link支持工业上最小的低成本智能传感器。

图1. Santa Cruz参考设计方框图。

特性 |

应用 |

竞争优势

|

|

Introduction

|

Since the 1980s, industrial field buses have allowed smarter devices, quicker installations, reduced wiring, and easier maintenance. However, the lack of a single, universally accepted field bus has also created confusion, training challenges, high costs, and compatibility issues among equipment.1IO-Link is the first open, field bus agnostic, low-cost, point-to-point serialcommunication protocol used for communicating with sensors and actuators that has been adopted as an international standard (IEC 61131-9).2 It finally standardizes interoperability with the industrial equipment from all over the world. IO-Link can exist directly from the PLC or can be integrated into all standard field buses, quickly making it the defacto standard for universally communicating with smart devices like the Santa Cruz (MAXREFDES23#). IO-Link, being simple yet intelligent, allows for the smallest low-cost smart sensors in the industry.

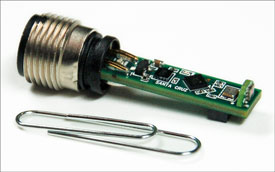

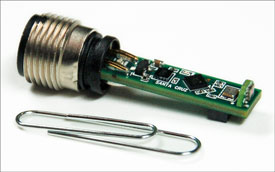

Santa Cruz is the world's smallest IO-Link light sensor with six integrated sensors ambient light (clear), red, green, blue,infrared, and temperature) all on a tiny printed circuit board (PCB) that is 6.5mm x 25mm. Maxim Integrated, Renesas®Electronics, and Technologie Management Gruppe Technologie und Engineering (TMG TE) collaborated in designing Santa Cruz as an IO-Link version 1.1/1.0 compliant light sensor reference design. The Santa Cruz design consists of an industry standard Maxim Integrated IO-Link device transceiver (MAX14821), a Renesas ultra-low-power, 16-bit microcontroller (RL78) utilizing TMG TE's IO-Link device stack and a Maxim Integrated light sensor (MAX44008). See Figure 1.

Figure 1. The Santa Cruz reference design block diagram.

Features |

Applications |

Competitive Advantages

|

|

详情介绍

Introduction

|

Since the 1980s, industrial field buses have allowed smarter devices, quicker installations, reduced wiring, and easier maintenance. However, the lack of a single, universally accepted field bus has also created confusion, training challenges, high costs, and compatibility issues among equipment.1 IO-Link is the first open, field bus diagnostic, low-cost, point-to-point serial communication protocol used for communicating with sensors and actuators that has been adopted as an international standard (IEC 61131-9).2 It finally standardizes interoperability with the industrial equipment from all over the world. IO-Link can exist directly from the PLC or can be integrated into all standard field buses, quickly making it the defacto standard for universally communicating with smart devices like the Santa Cruz (MAXREFDES23#). IO-Link, being simple yet intelligent, allows for the smallest low-cost smart sensors in the industry.

Santa Cruz is the world's smallest IO-Link light sensor with six integrated sensors: ambient light (clear), red, green, blue, infrared, and temperature all on a tiny printed circuit board (PCB) that is 6.5mm x 25mm. Maxim Integrated, Renesas® Electronics, and Technologie Management Gruppe Technologie und Engineering (TMG TE) collaborated in designing Santa Cruz as an IO-Link version 1.1/1.0 compliant light sensor reference design. The Santa Cruz design consists of an industry standard Maxim Integrated IO-Link device transceiver (MAX14821), a Renesas ultra-low-power, 16-bit microcontroller (RL78) utilizing TMG TE's IO-Link device stack and a Maxim Integrated light sensor (MAX44008). See Figure 1.

Figure 1. The Santa Cruz reference design block diagram.

Features |

Applications |

Competitive Advantages

|

|

Detailed Description of Hardware

Santa Cruz is size optimized to meet industrial control and automation light-sensing applications where space is limited. The case sizes of the discrete components were carefully selected to ensure they meet the harsh conditions in an industrial environment.

The MAX14821 IO-Link device transceiver is IO-Link version 1.1/1.0 physical layer compliant with integrated 3.3V/5V linear regulators, configurable outputs (push-pull, pnp or npn), reverse-polarity/short-circuit protection, extensive fault monitoring all in a tiny 2.5mm x 2.5mm WLP package.

The ambient light (clear), red, green, blue, infrared, and temperature data can be read continuously from the MAX44008 through an I2C interface. The light sensor has six integrated sensors with each sensor having its own on-chip dedicated PGA and 14-bit ADC inside a miniature optical 2mm x 2mm OTDFN package. Receiving light at a right angle to the board edge is important to allow compatibility with an M12 circular housing and avoid the high cost of custom light pipes.This is the reason why the MAX44008 is placed on an extremely small half moon shaped board (MAXREFDES26#) that is then soldered onto the tip of the Santa Cruz board as shown in Figure 2.

An ultra-low-power RL78/G1A microcontroller with current consumption down to 66µA/MHz provides system control on Santa Cruz. It features 64KB on-chip programmable flash memory, 4KB on-chip data flash, and operates down to 1.8V, all in a tiny 3mm x 3mm LGA package.

Transient voltage suppressor (TVS) diodes are not all equal. The SDC36 TVS diodes have a clamping voltage less than 55V and meet both IEC 61000-4-2 (ESD) and IEC 61000-4-4 (EFT). There are many smaller TVS diodes out there that can't meet all of these specifications.

Care must be taken when selecting resistors in a 24V (18V to 30V) system. Though designers may need the smallest size components, avoid using resistors in an 0201 case size if they connect to 24V during normal operation. Resistors can fail by exceeding their maximum working voltage even if their maximum power rating is not exceeded.

Santa Cruz uses an industry standard M12 connector allowing a 4-wire, or the conventional 3-wire, cable to be used to, keeping costs low. The conventional way of adding six binary sensors would have required six sets of 3-wire cables. Now instead of six binary sensors,six smart 14-bit sensors on a single IO-Link channel need only a single 3-wire cable. Santa Cruz does all this while consuming less than 12mA (typ).

Figure 2. The Santa Cruz reference design next to a standard AAA battery.

Detailed Description of Software

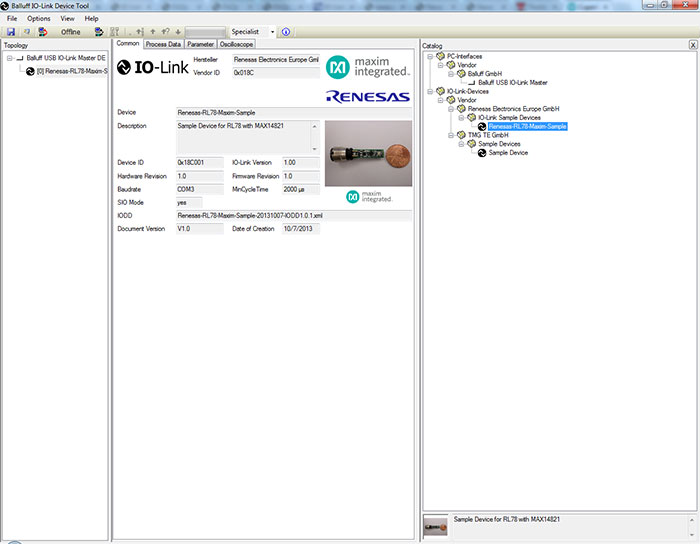

The Santa Cruz was verified using TMG TE's TMG IO-Link Device Tool V3, which comes with the purchase of the TMG-USB IO-Link master TS hardware. Contact TMG TE for more information. Santa Cruz was also verified using Balluff's IO-Link Device Tool version 2.11.1, which comes with the purchase of the Balluff USB IO-Link master, part number BNI USB-901-000-A501. Contact Balluff or one of their local distributors for ordering information. Download the IODD file (*.xml) located in the All Design Files section at the end of this document and go to the Quick Start section below for step-by-step instructions on how to use the software. Figure 3 shows a screen shot of the Balluff IO-Link Device Tool.

IQ2 Development also has an IO-Link device stack that has been ported to the MAXREFDES23#. Their latest source code and documentation is available at the links below.

http://iq2-development.com/downloads

http://iq2-development.com/iqmaxrefdes23

For more information about IQ2 Development's IO-Link device stack please contact them at:

Figure 3. Balluff's IO-Link Device Tool version 2.11.1.

Detailed Description of Firmware

The Santa Cruz ships pre-programmed as a working IO-Link light sensor ready to connect to an IO-Link master. The firmware targets a Renesas RL78 microcontroller and follows the simple flow chart shown in Figure 4. The firmware is written in C using the IAR embedded workbench from IAR Systems and utilizes TMG TE's IO-Link device stack.

Figure 4. The Santa Cruz firmware flow chart.

After hot plug-in, Santa Cruz waits for a wake-up signal from the IO-Link master. Once the wake-up signal is received, Santa Cruz synchronizes to the IO-Link master's 230.4kbps baud rate (COM3). Communication parameters are exchanged. Santa Cruz then starts a cyclic data exchange every 2ms by sending the sensor process data to the IO-Link master. If the sensor is removed, the IO-Link master will detect a missing sensor.

Detailed Description of Use Cases

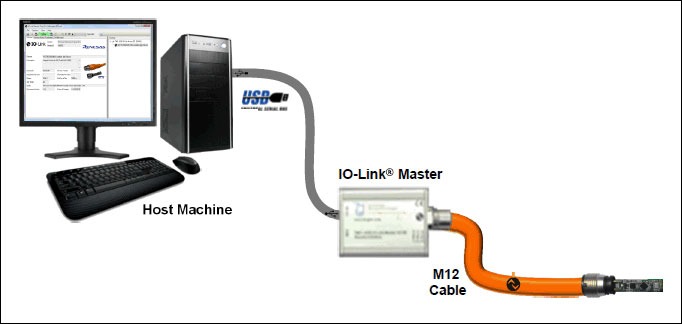

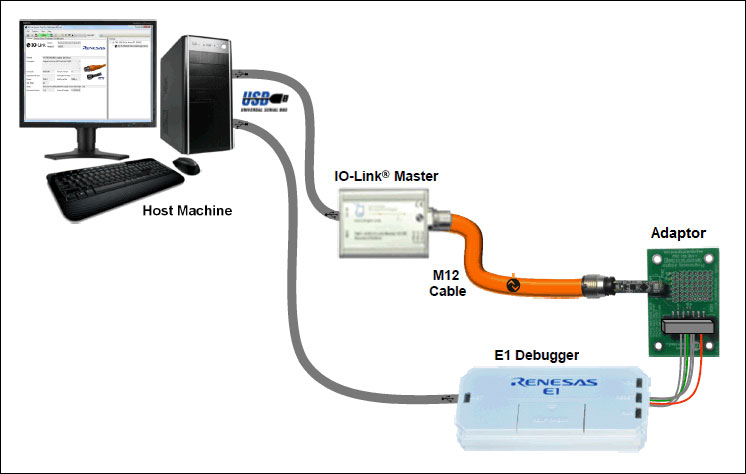

There are two different use cases that you should consider before purchasing Santa Cruz. Use case #1 is simply using the Santa Cruz, which is pre-programmed right out of the box to connect with a user-supplied IO-Link master and IO-Link cable as shown in Figure 5. Use case #2 is where the entire firmware development system is needed as shown in Figure 6.

Figure 5. Use case #1 is the Santa Cruz quick start system.

Table 1. Recommended Components Needed for Use Case #1

| Use Case #1 (Santa Cruz quick start system) | ||

|---|---|---|

| Company | Description | Orderable Part Number |

| Maxim Integrated | Santa Cruz IO-Link Light Sensor Includes: Half moon board |

MAXREFDES23# |

| Balluff | USB IO-Link Master | BNI USB-901-000-A501 |

| Balluff | IO-Link Cable (4-wire/2m) | BCC05MC |

Figure 6. Use case #2 is the Santa Cruz firmware development system.

Table 2. Recommended Components Needed for Use Case #2

| Use Case #2 (Santa Cruz firmware development system—Renesas Starter Kit) | ||

|---|---|---|

| Company | Description | Orderable Part Number |

| Renesas Electronics | Renesas Starter Kit Includes: IAR Embedded Workbench for Renesas RL78 Santa Cruz (MAXREFDES23#) Programming Adaptor (MAXREFDES23DB#) |

Contact Renesas |

| Renesas Electronics | E1 Programmer/Debugger | R0E000010KCE00 |

| Balluff | USB IO-Link Master | BNI USB-901-000-A501 |

| Balluff | IO-Link Cable (4-wire/2m) | BCC05MC |

Source code is only provided with use case #2, which is the Renesas Starter Kit. Contact Renesas Electronics for more information.

Quick Start (Use Case #1)

Required Equipment:

Purchased from Maxim:

- Santa Cruz (MAXREFDES23#) board

User supplied:

- Windows® PC with a USB port

- Balluff USB IO-Link master, part number BNI USB-901-000-A501

- Balluff IO-Link Device Tool (tested with version 2.11.1 and comes with IO-Link master)

- M12 4-pin or 3-pin IO-Link cable (BCC05MC)

Note: Verify with Balluff that your version of Windows is supported before purchasing their software.

Download, read, and carefully follow each step in the Santa Cruz Quick Start Guide.

Lab Measurements

Equipment Used:

- Thorlabs MCWHL5—cold white mounted high-power LED, 1000mA

- Thorlabs DC2100—high-power, 1-channel LED driver with pulse modulation, 2A, 24V

- Thorlabs CR1-27—continuous rotation stage

- Thorlabs TDC001—T-cube DC servo motor controller

- Thorlabs PM100D—compact power and energy meter console, digital 4in LCD

- Windows 7 PC with USB port

- Santa Cruz (MAXREFDES23#) board

- Programming adapter (MAXREFDES23DB#) board

- Balluff USB IO-Link master, part number BNI USB-901-000-A501

- Balluff IO-Link Device Tool (tested with version 2.11.1 and comes with IO-Link master)

- M12 4-pin or 3-pin IO-Link cable

- RD23_RL78_VXX_XX.ZIP (IODD file); where XX_XX = latest version from webpage

- Tektronix® TDS2024B—4-channel 200MHz/2GSps oscilloscope

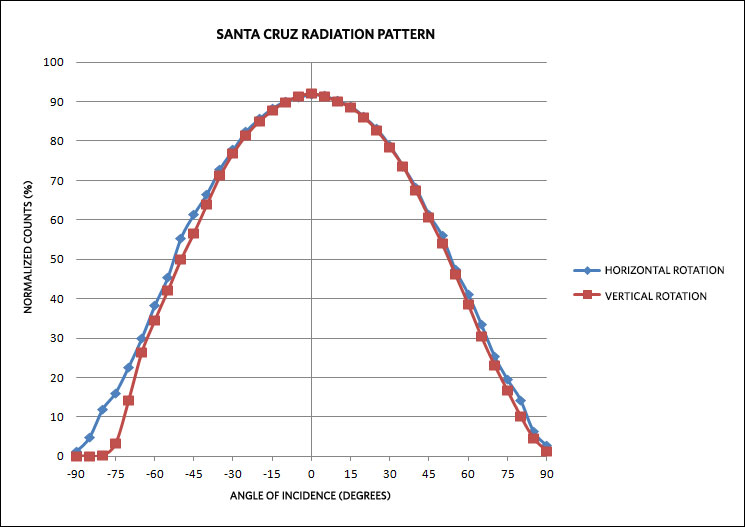

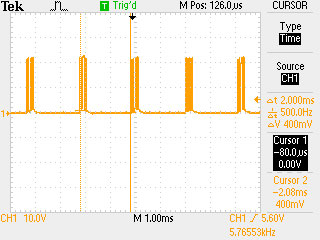

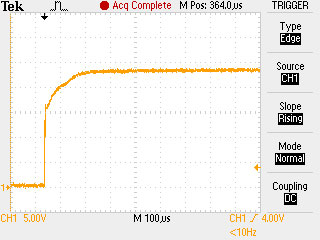

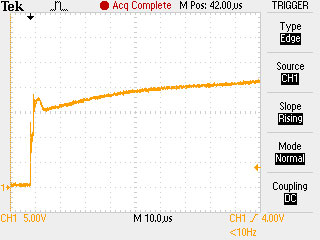

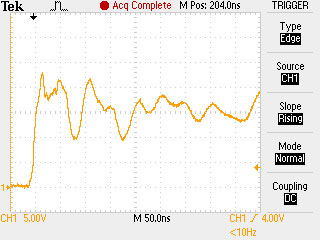

Special care must be taken and the proper equipment must be used when testing the Santa Cruz design. The key to testing any high-accuracy design is to use sources and measurement equipment that are higher accuracy than the design under test. The equipment from Thorlabs and the Tektronix oscilloscope were appropriate equipment choices for these lab measurements. Figure 7 shows how well Santa Cruz's readings match with changes in angle of incidence from both horizontal and vertical rotation. These measurements were taken without a sensor enclosure lens and also without a sensor enclosure. Figure 8 shows the Santa Cruz doing a 2ms cyclic data exchange with the IO-Link master. The Santa Cruz is robust in handling hot plug-in events without failing, essential for every sensor, and shown in Figures 9–11.

Figure 7. Santa Cruz clear radiation pattern with the conditions of AMBPGA [1:0] = 00, AMBTIM [2:0] = 000.

Figure 8. Cyclic data exchange every 2ms from the Santa Cruz to the IO-Link master.

Figure 9. A 100µs time base oscilloscope shot of the 24V supply being hot-plugged into the Santa Cruz (M12-1).

Figure 10. A 10µs time base oscilloscope shot of the 24V supply being hot-plugged into the Santa Cruz (M12-1).

Figure 11. A 50ns time base oscilloscope shot of the 24V supply being hot-plugged into the Santa Cruz (M12-1).

References

- Fieldbus Inc's IEC61158 Technology Comparison study, Slide 58: "Fieldbus Technology Challenges".

- IO-Link System Description 2013 by IO-Link Company Community. Page 3 , Preface.

IO-Link is a registered trademark of ifm electronic GmbH.

Renesas is a registered trademark and registered service mark of Renesas Electronics Corporation.

Tektronix is a registered trademark and registered service mark of Tektronix, Inc.

Windows is a registered trademark and registered service mark of Microsoft Corporation.