PALO VERDE (MAXREFDES33#):降压转换器

概述

|

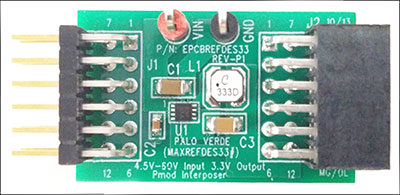

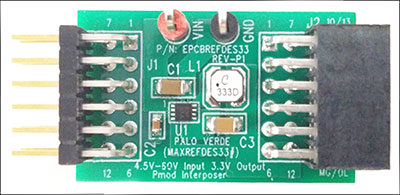

Palo Verde (MAXREFDES33#)子系统参考设计(图1)演示MAX15062A 60V、300mA、超小尺寸、高效率、同步型降压转换器的应用。参考设计工作在4.5V至60V较宽输入电压范围,提供高达300mA @ 3.3V输出。器件具有欠压锁定、过流保护以及热关断。MAX15062A的开关频率固定为500kHz,输入为24V时,利用提供的元件可实现86.77%的最高效率。该通用电源方案可用于多种不同类型的应用,例如4–20mA电流环路、HVAC与楼宇控制、替代高压LDO、通用负载点,等等。本参考设计中,MAX15062支持24V输入应用,例如工业传感器、过程控制等。

系统框图

图1. 典型工业控制电源系统框图。

特性 |

应用 |

|

|

详情介绍

Introduction

|

The Palo Verde (MAXREFDES33#) subsystem reference design (Figure 1) demonstrates the application of theMAX15062A 60V, 300mA ultra-small, high-efficiency, synchronous step-down converter. The reference design operates over a wide 4.5V to 60V input voltage range, and provides up to 300mA at 3.3V output. The device features undervoltage lockout, overcurrent protection, and thermal shutdown. The MAX15062A switches at a fixed frequency of 500kHz, and delivers a peak efficiency of 86.77% with the supplied components when the input is 24V. This general-purpose power solution can be used in many different types of power applications, such as 4–20mA current loops, HVAC and building control, high-voltage LDO replacement, general-purpose point-of-load, etc. In this reference design, the MAX15062 performs in 24V input applications, such as industrial sensors, process control, etc.

System Diagram

Figure 1. Typical industrial control power system diagram.

Features |

Applications |

|

|

Detailed Description of Hardware

The Palo Verde subsystem reference design is a high-efficiency, high-voltage, synchronous step-down DC-DC converter solution with integrated MOSFETs. Palo Verde operates over a wide 4.5V to 60V input voltage range. The converter delivers output current up to 300mA at 3.3V. When EN/UVLO and VCC UVLO are satisfied, an internal power-up sequence soft-starts the error-amplifier reference, resulting in a clean monotonic output-voltage soft-start independent of the load current. The VOUT pin monitors the output voltage through an internal resistor-divider. RESET transitions to a high-impedance state 2ms after the output voltage reaches 95% of regulation. The device selects either PFM or forced-PWM mode depending on the state of the MODE pin at power-up (this reference design sets the device in PWM mode). By pulling the EN/UVLO pin to low, the device enters the shutdown mode and consumes only 2.2µA (typical) of standby current.

The reference design switches at a fixed frequency of 500kHz, and delivers a peak efficiency of 86.77% with the supplied components when the input is 24V.

This reference board is designed in a Pmod-compatible form factor with IO pass-through, but can be used in any 4.5V–60V to 3.3V power application up to 300mA.

Quick Start

Required equipment:

Procedure

- Turn off the power supply.

- Connect the positive terminal of the power supply to the VIN connector of the MAXREFDES33# board.

- Connect the negative terminal of the power supply to the GND connector of the MAXREFDES33# board.

- Connect the positive terminal of the electronic load to J2-6 of the MAXREFDES33# board.

- Connect the negative terminal of the electronic load to J2-5 of the MAXREFDES33# board.

- Connect the positive terminal of the voltmeter to the positive terminal of the electronic load.

- Connect the negative terminal of the voltmeter to the negative terminal of the electronic load.

- Turn on the power supply.

- Set the electronic load to a constant current between 0 to 300mA.

- Verify the voltmeter reading is 3.3V ±0.05V.

Lab Measurements

The Palo Verde design was tested using a 24V input voltage. The performance under other input conditions can be captured with a similar setup. Refer to the MAX15062 data sheet for detailed performances in other application conditions.

The power efficiency vs load current is illustrated in Figure 2.

Figure 2. Power efficiency vs. current load for 24V input.

Figure 3 and Figure 4 display the ripple at no load (ripple is 6mV peak-peak) and 300mA load (ripple is 8mV peak-peak), respectively. Channel 1 in the oscilloscope screen shot is voltage at the LX pin. Channel 2 in the oscilloscope screen shot is voltage at the VOUT pin.

Figure 3. Output ripple at 0mA load.

Figure 4. Output ripple at 300mA load.

Figure 5 displays the load transient response when the load is stepped from 5mA to 150mA, and then dropped back to 5mA again.The transient voltage is about 60mV.

Figure 5. Transient response when load steps from 5mA to 150mA.

Figure 6 displays the load transient response when the load is stepped from 150mA to 300mA, and then dropped back to 150mA again.The transient voltage is also about 60mV.

Figure 6. Transient response when load steps from 150mA to 300mA.