MAXREFDES46#:4通道模拟输入/输出

MAXREFDES46#为一个小巧的模拟远程终端装置(RTU), 带可编程逻辑控制器(PLC)。提供四路高精度隔离的模拟输入和四路高精度隔离的模拟输出。除了一个调试用的USB接口外,还提供了一个隔离的RS-485接口。采用24V直流电源。测试数据表明,高速信号和直流信号都表现出优异的性能。

关于实验室测量数据的更多信息,请参考详细资料标签页。从设计资源标签页可下载设计文件和固件。

特性

- 可编程高精度电流/电压输出

- 高精度

- ±10V,0至10V和4–20mA输入

- 电流输出驱动0到1kΩ

- 电压输出驱动低至1kΩ的负载

- 齐全的出错报告

- 电源与数字信号隔离

- 器件驱动器

- C语言源代码示例

竞争优势

- 灵活性

- 系统安全

- 方案尺寸小

应用

- PLC

- DCS

- 分布式I/O

- 嵌入式系统

- 工业控制和自动化

详情介绍

Introduction

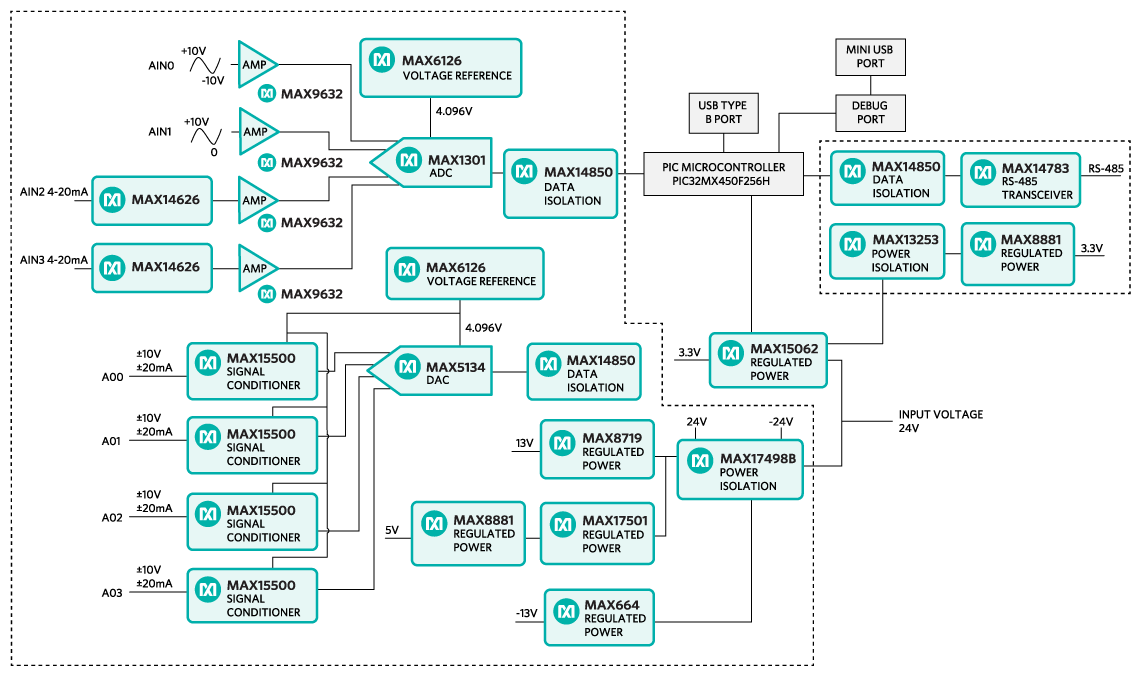

In programmable logic controllers (PLC) and distributed control systems (DCS), analog input current and voltage measurements provide critical sensor data, while analog output currents and voltages provide critical control and actuation functions. The MAXREFDES46# reference design, shown in Figure 1, features four flexible and programmable analog inputs and outputs that meet industrial process and control requirements.

For analog inputs, the MAX1301 is the heart of analog input section. This four channel, 16-bit, high-accuracy analog to digital converter (ADC) provides measurement of voltage inputs from the op-amp signal conditioning circuits, MAX9632. The current and voltage signals from industrial sensors get processed for impedance balance, protection and removal of noise by the signal conditioning circuit. The MAX6126 produces an ultra-high-precision voltage reference for the ADC.

For analog outputs, the MAX5134 lies at the center of the system. This four channel, 16-bit, high-accuracy digital-to-analog converter (DAC) provides voltage outputs that drive the inputs of four MAX15500 signal conditioners. These signal conditioners produce accurate current or voltage outputs, programmable by the user. The MAX15500 also provides extensive error reporting. The MAX6126 also produces an ultra-high-precision voltage reference for the DAC and the output conditioners.

The MAX14850 galvanically isolates data communication between the analog subsystem and the system controller. The system integrates a 42Mbps RS-485 transceiver, MAX14783, with tested throughput of 20Mbps for communicating with remote host. The system also utilizes a PIC32 microcontroller to provide complete autonomy and intelligence.

MAXREFDES46# also integrates an isolated, wide DC input range, flyback converter power supply. The peak current-mode flyback controller, MAX17498B, efficiently drives an isolated transformer and generates ±24V and ±15V outputs. The MAX8719 and MAX664 low dropout (LDO) linear regulators then regulate the ±15V output to low-noise +13V and -13V output rails, respectively. The synchronous step down DC-DC converter, MAX17501, in conjunction with MAX8881 LDO, generate a low noise 5V supply required for ADC and DAC section. The synchronous step down DC-DC converter, MAX15062, generates the 3.3V required for digital MCU section. The push pull transformer driver, MAX13253, along with MAX8881, generate the galvanically isolated 3.3V supply required for RS-485 section.

The entire system requires only a 24V input for power.

The analog subsystem features all typical unipolar current and unipolar/bipolar voltage output ranges, and appropriate subsets, with less than ±0.1% typical total unadjusted error (TUE). The circuit also provides short-circuit and overcurrent protection, open circuit detection, brownout detection, and over temperature protection. All such protections are which are critical for industrial applications. Flexible power-up options make MAXREFDES46# an ideal choice for robust industrial control systems.

Figure 1. The MAXREFDES46subsystem design block diagram.

Figure 1. The MAXREFDES46subsystem design block diagram.

Table 1. Power Requirements for the MAXREFDES46# Reference Design

| Power Name | Input Voltage (V) | Input Current (mA, MAX) |

|---|---|---|

| +24V | 21 to 27 | 400 |

Detailed Description of Hardware

The MAX15500 (U24-U27) is a single-channel, low-cost, precision analog current/voltage output conditioner developed to meet the requirements of PLCs and other industrial control and automation applications. The MAX15500 operates from a ±24V power-supply range.

The MAX15500 generates both unipolar and bipolar current and voltage outputs. In current mode, the device produces currents from -1.2mA to +24mA or -24mA to +24mA. In voltage mode, the device produces voltages of -0.3V to +6V, -0.6V to +12V, or ±12V. To allow for over range and under range capability in unipolar mode, the transfer function of the MAX15500 is offset so that when the voltage at AIN is 5% of full scale, IOUT is 0mA and VOUT is 0V. Once VAIN attains full scale, VOUT or IOUT becomes full scale +5% or +20% depending on the state of FSMODE.

The MAX15500 protects against overcurrent and short-circuit condi¬tions when OUT goes to ground or a voltage up to ±32.5V. The device also monitors for over temperature and supply brownout conditions. The supply brownout threshold is programmable between ±10V and ±24V in 2V increments. The MAX15500 provides extensive error reporting of short-circuit, open-circuit, brownout, and over temperature conditions through the SPI interface and an additional open-drain interrupt output (ERROR). The MAX15500 also includes an analog 0 to 3V output (MON) to monitor the load condi¬tion at OUT.

The MAX5134 (U16) is a quad 16-bit, buffered voltage-output, high-linearity DAC. The device features 4-channel, very low dead band (0.02V max) rail-to-rail outputs. For most applications, no negative biasing power supply is required.

The MAX6126 (U17) provides the analog output conditioners and the DAC's reference inputs with an ultra-high-precision 4.096V voltage reference with 0.02% initial accuracy and a 3ppm/°C maximum temperature coefficient. The DAC outputs directly drive the conditioners’ inputs with no external components, making the interface simple.

The MAX1301 (U22) is a 16-bit, successive-approximation register (SAR) ADC with unique multi-range inputs capable of accepting input voltage signals up to +12.288V to -12.288V. The ADC also has integrated analog input buffers with a 17kΩ input resistance.

The MAX9632 amplifiers (U30, U31) are optimized for low-noise, -10V to +10V and 0 to +10V input voltages, and (U28, U29) for low-noise, 4–20mA input currents. MAX9632 provides high input impedance for input signals that have a large source resistance, or in the case of the 4–20mA loop, a 250Ω load resistance.

Although the MAX1301 ADC has an internal 4.096V voltage reference, for highest accuracy, use the external MAX6126 (U21) voltage reference with 0.02% initial accuracy and a 3ppm/°C maximum temperature coefficient (tempco).

The MAX17498B (U6) provides an isolated, functional insulation class power solution that accepts single +21V to +27V DC voltage and converts it to ±24V and ±15V using an isolation transformer in flyback architecture. Post-regulation is accomplished using the MAX17501 DC-DC converter (U18) with MAX8881 LDO (U19) for the 5V output; MAX8719 LDO (U20) and MAX664 LDO (U23) for ±13V from ±15V; MAX15062 DC-DC converter (U2) for 3.3V_MCU from 24V; MAX13253 push pull transformer driver (U9) along with MAX8881 LDO (U8) for isolated 3.3V_RS485 from 3.3V_MCU.

Data isolation between the subsystem and the controller is accomplished using the MAX14850 (U7) digital data isolator. The combined power and data isolation achieved is 600VRMS.

Detailed Description of Firmware for PIC32 platform

Figure 2. The MAXREFDES46 firmware flowchart.

Figure 2. The MAXREFDES46 firmware flowchart.

The complete source code is provided to speed up customer development. Code documentation can be found with the corresponding firmware platform files.

Quick Start

Required equipment:

- Windows® PC with two USB ports

- MAXREFDES46# board

- One 24V, 400mA minimum DC power supply (provided with MAXREFDES46# board)

- USB type A to type B cable

- USB type A to mini USB cable

- USB to RS-485 converter

Download, read, and carefully follow each step in the MAXREFDES46 Quick Start Guide.

Lab Measurements

Equipment Used:

- MAXREFDES46# board

- One 750Ω, 0.25W resistor load

- One 1KΩ, 0.25W resistor load

- Agilent 3458A digital multimeter

- Agilent E3631A DC power supply (any 24V, 400mA minimum DC power supply works)

- National Instruments GPIB card and cable

- Thermonics T-2800 precision temperature forcing system

- Windows PC

- Audio Precision® SYS-2722 signal source or equivalent

Special care must be taken and the proper equipment must be used when testing the MAXREFDES46# design. The key to testing any high-accuracy design is to use sources and measurement equipment that are of higher accuracy than the design under test. A low distortion signal source is absolutely required in order to duplicate the results presented below. The input signal was generated using the Audio Precision SYS-2722. The analog inputs should be driven with a source and not be left floating. The FFTs were created using the FFT control in SignalLab from Mitov Software. All lab measurements were done at room temperature.

Measurements of AC FFT for channel 0 (AIN0) using on-board isolated power with 1KHz, ±10V input signal from SYS2722 audio generator.

Figure 3. AC FFT for channel 0 (AIN0) using on-board isolated power, a ±10V 1kHz sine wave input signal, high-impedance input, a 20ksps sample rate, and a Blackman-Harris window.

Figure 3. AC FFT for channel 0 (AIN0) using on-board isolated power, a ±10V 1kHz sine wave input signal, high-impedance input, a 20ksps sample rate, and a Blackman-Harris window.

Measurements of AC FFT for channel 0 (AIN0) using on-board isolated power with 250Hz, ±10V input signal from SYS2722 audio generator.

Figure 4. AC FFT for channel 0 (AIN0) using on-board isolated power, a ±10V 250Hz sine wave input signal, high-impedance input, a 5ksps sample rate, and a Blackman-Harris window.

Figure 4. AC FFT for channel 0 (AIN0) using on-board isolated power, a ±10V 250Hz sine wave input signal, high-impedance input, a 5ksps sample rate, and a Blackman-Harris window.

Measurements of DC histogram for channel 0 (AIN0) using on-board isolated power with input grounded.

Figure 5. DC histogram for channel 0 (AIN0) using on-board isolated power; a 0V input signal; high-impedance input; a 20ksps sample rate; 65,536 samples; a code spread of 7 LSBs with 98.1% of the codes falling within the three center LSBs; and a standard deviation of 0.660.

Figure 5. DC histogram for channel 0 (AIN0) using on-board isolated power; a 0V input signal; high-impedance input; a 20ksps sample rate; 65,536 samples; a code spread of 7 LSBs with 98.1% of the codes falling within the three center LSBs; and a standard deviation of 0.660.

Figure 6. DC histogram for channel 0 (AIN0) using on-board isolated power; a 0V input signal; high-impedance input; a 5ksps sample rate; 65,536 samples; a code spread of 7 LSBs with 98.35% of the codes falling within the three center LSBs; and a standard deviation of 0.664.

Figure 6. DC histogram for channel 0 (AIN0) using on-board isolated power; a 0V input signal; high-impedance input; a 5ksps sample rate; 65,536 samples; a code spread of 7 LSBs with 98.35% of the codes falling within the three center LSBs; and a standard deviation of 0.664.

INL, DNL, and total unadjusted error (TUE) are the most important specifications for PLC and other process control systems. The MAX15500 is highly flexible and configurable to meet the needs of various applications. The data was taken at +25°C. In the following pictures, the DNL, INL, and TUE for the first 320 DAC codes are shown as 0 because codes 0 to 320 are in the deadband (0 to 0.02V) of the MAX5134.

Measurements of DNL, INL, and TUE for the -10V to +10V voltage output mode, with 20% over range are shown in Figure 7, Figure 8, and Figure 9, respectively.

Figure 7. DNL for -10V to +10V output range, with 20% overrange.

Figure 7. DNL for -10V to +10V output range, with 20% overrange.

Figure 8. INL for -10V to +10V output range, with 20% overrange.

Figure 8. INL for -10V to +10V output range, with 20% overrange.

Figure 9. Output error for -10V to +10V output range, with 20% overrange.

Figure 9. Output error for -10V to +10V output range, with 20% overrange.

Measurements of DNL, INL, and TUE for the 0 to 10V voltage output mode, with 20% over range are shown in Figure 10, Figure 11, and Figure 12, respectively.

Figure 10. DNL for 0 to 10V output range, with 20% over range.

Figure 10. DNL for 0 to 10V output range, with 20% over range.

Figure 11. INL for 0 to 10V output range, with 20% overrange.

Figure 11. INL for 0 to 10V output range, with 20% overrange.

Figure 12. Output error for 0 to 10V output range, with 20% overrange.

Figure 12. Output error for 0 to 10V output range, with 20% overrange.

Windows is a registered trademark and registered service mark of Microsoft Corporation.