Powertrain & EV Charging

详情介绍

Optimizing Automotive Powertrain Designs

At Microsemi, we’re focused on delivering the right combination of performance, durability, reliability and quality to help you optimize your most demanding designs. Undoubtedly, in next-generation electric vehicles (EVs), power and efficiency are critical. This is especially true as the number of engine control units (ECUs) within the car grows exponentially. Predictability and isolation of safety-critical functions becomes increasingly complex, particularly when aggregating several functions onto fewer nodes. These factors drive the need for reprogrammable computational capabilities, along with sensor and power management solutions to optimize system efficiency.

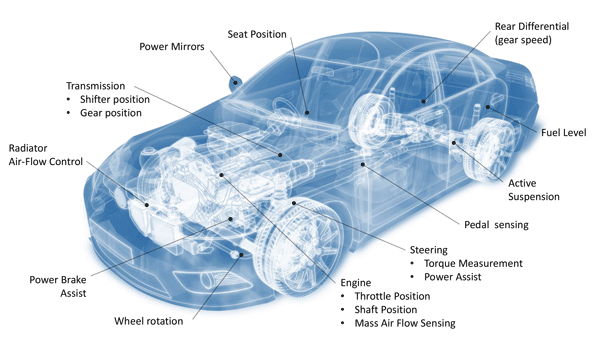

Microsemi’s automotive sensor interface microcontroller portfolio can be used flexibly as position, rotary and angular sensors. The inductive sensor ICs can also be applied as linear variable differential transformer (LVDTs) to measure linear motion or displacement (position).

Microsemi’s portfolio for automotive powertrain and EV charging applications includes:

- Sensor interface ICs targeted at a variety of automotive sub-systems such as engine, pedals, steering wheel and gearbox.

- Power management devices for EV power train and charging.

- Automotive-grade FPGAs & SoCs for reprogrammable compute abilities within EV powertrains.

Microsemi is a long-time supplier of high-reliability, high-performance solutions in the aerospace, communications, defense/security and industrial markets. We are uniquely able to leverage our rich DNA to transition our technology and expertise to meet the demanding requirements of the automotive design community.

Contact your local Microsemi sales office today to find the right technologies and products for your automotive powertrain and EV charging needs.

Automotive Sensors

Microsemi has been shipping automotive sensor ICs in volume since 2010, delivering precision analog front end (AFE) custom products for pedals, steering and active suspension, as well as MCU-based motion measurement.

Industry data forecasts global shipments of new light vehicles to reach 110 million by 2020, growing from nearly 85 million in 2014. Sensors are key elements in the feedback loop of any control system. While current cars average 60-100 on-board sensors, this number is projected to potentially more than double as cars become increasingly “smart” and connected. This translates to a projected 22 billion sensors used on-board vehicles by 2020.

The LX3301A and LX3302 are the first members of Microsemi’s advanced microcontroller-based sensor interface IC family are ideal for a variety of automotive sub-systems such as pedals, engine, gearbox and steering wheel. Microsemi’s inductive sensors deliver higher precision, higher reliability and lower cost than hall-effect sensors. Microsemi also offers the industry’s only turnkey, fully integrated solution with sensor interface, MCU and firmware.

Contact your local Microsemi sales office today to find the right sensor interface ICs for your automotive designs

Increasing EV Charging Efficiencies

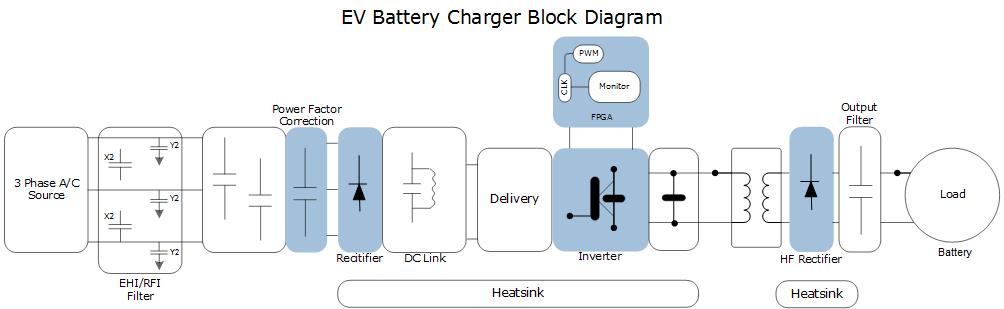

For electric vehicle (EV) power train and car charger applications, Microsemi offers a portfolio of high-performance diodes, diode modules, IGBTs, IGBT modules, MOSFETs, MOSFET modules, silicon Carbide (SiC) MOSFETs, SiC Schottky diodes and SiC power modules, as well as Power Line Communication (PLC) line drivers.Explore Microsemi’s product portfolio for EV power train and charging:

- Diodes

- Diode modules

- IGBTs

- IGBT modules

- MOSFETs

- MOSFET modules

- SiC MOSFETs

- SiC Schottky diodes

- SiC power modules

- PLC line drivers

According to estimates from a leading Japanese automaker, 20% of HV total electrical power loss occurs in the power semiconductors. This makes improving power semiconductor efficiency critical to improving fuel efficiency. SiC technology is key to these power semiconductor efficiency improvements, decreasing semiconductor size and reducing power system loss by up to 50%.

Microsemi's SiC MOSFETs, Shottky diodes and power modules deliver superior dynamic and thermal performance versus conventional silicon power diodes. Microsemi PLC line drivers for EV charging are featured in reference designs from leading broadband SoC providers.

Microsemi offers a broad portfolio of ICs and systems solutions for applications ranging from communications, aerospace, defense and security, as well as industrial. Microsemi’s diverse offering includes analog mixed signal ICs; FPGAs, SoC and ASICs; power management, timing and voice processing ICs, RF solutions; Ethernet solutions; Power over Ethernet (PoE) ICs and midspans, and discrete components.

Contact your local Microsemi sales office today to find the right products for your EV power train and charging needs.

Reduce Automotive ECU Complexities with Reprogrammable Computing

Functionality of the engine control units (ECUs) within cars is more advanced than ever, as automakers look to improve driver safety and the overall driving experience. FPGAs and SoCs will play a critical role within next-gen automotive electronics systems, which are increasingly dense in order to meet the growing functional demands within new cars.

Microsemi’s non-volatile flash based FPGAs offer realization of fail-safe and reliable systems. In addition, they offer the benefits of reprogrammability, best-in-class security, high reliability (extended temperature support), SEU immunity and hardware configurability.

Microsemi SmartFusion2 and IGLOO2 devices are instant-on and require no external configuration device and thereby greatly minimize component count, configuration errors and vulnerability to hacking during configuration. Microsemi offers ease of configuration whenever there is change in application design or large scale platform migration and long support cycles. These benefits translate to lower total cost of ownership and assurance of lifetime product support.

Explore Microsemi’s portfolio of automotive-grade FPGAs and SoCs for your next-gen EV powertrain designs:

Benefits of Microsemi FPGAs in Specialised ECU

Benefits of Microsemi FPGAs in Specialised ECU

- Extended temperature support (Tj=135°C)

- Elimination of redundant systems to enable fail-safe applications.

- SEU immunity and protection from firm errors

- Advanced biometric SRAM-based PUF protected data - protection of customer “secret sauce”

- Secure configuration bitstreams via encryption and protection from side channel attacks

- Ease of configuration and long support cycle for application redesign or platform migration

- Low total cost of ownership

Contact your local Microsemi sales office today to find the right products for your EV power train and charging needs.